A University of Houston researcher is trying a novel approach to create high efficiency, low cost solar cells in an effort to bring the cost down to that of traditional electricity sources.

Venkat Selvamanickam, M.D. Anderson Chair professor of mechanical engineering and director of the Applied Research Hub at the Texas Center for Superconductivity at UH, received a $1,499,994 grant from the U.S. Department of Energy SunShot Initiative to produce high efficiency, inexpensive thin film photovoltaics.

The grant is part of the department’s SunShot Initiative, created in 2011 to make solar energy cost-competitive with other forms of electricity by the end of the decade. Since then, it has funded more than 350 projects, with a goal of bringing the cost of solar electricity to about $0.06 per kilowatt-hour.

Selvamanickam, whose lab already produces thin film superconducting wire, said he began thinking several years ago about developing a technique to produce solar cells using a technique similar to the one he uses for coating semiconductors as thin films on low-cost metal substrates, based on a similar roll-to-roll manufacturing technology.

The solar cells targeted by Selvamanickam are different from the solar panels people are accustomed to seeing on rooftops. Solar cells traditionally are produced on silicon wafers, while the most efficient solar cells are composed of a germanium wafer, topped with gallium-arsenide.

But that type of solar cell is expensive, Selvamanickam said, both because of the high costs of the germanium wafer and the manufacturing process. And the germanium wafers are small, requiring a large number to cover much area. Consequently, they are used mainly for space applications.

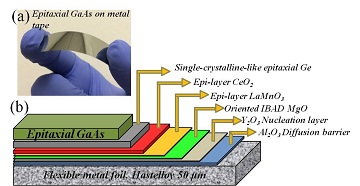

His process involves using a metal foil tape with a germanium thin film – although he said another substance could be used as a base – and moving it at high speed with the roll-to-roll technology, coating it in a vacuum chamber with vapors of gallium and arsine.

The work is being done in Selvamanickam’s Energy Devices Fabrication Laboratory at the UH Energy Research Park. The Energy Research Park was established by the University in 2010 to conduct translational research to rapidly develop and transfer new technologies to industry. The new project with SunShot will be conducted in collaboration with the South Dakota School of Mines and Technology.

Selvamanickam said his team presented proof-of-concept with his application to the Energy Department, showing high-quality gallium arsenide thin films on metal foils. Those results were published in the journal Applied Physics Letters in September.

Other researchers have used roll-to-roll manufacturing technology for solar cells but not with the germanium-gallium-arsenide materials and so they had much lower efficiency, he said.

Single-junction solar cells on germanium wafers produced with gallium-arsenide can operate at an efficiency of 28.5 percent, with a cost of several dollars per watt. Selvamanickam’s goal is to produce a solar cell that operates at 24 percent efficiency at a cost of 20 cents per watt.