A Look Back at 50 Years in the Printing Industry

March 19, 2019

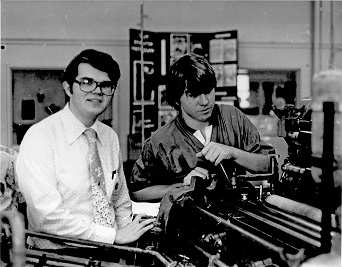

Professor Jerry Waite, program coordinator of the University of Houston College of Technology Digital Media Program, is celebrating his 50th year in the printing industry. It’s a career that started in the photolithography program at Don Bosco Technical High School (Bosco Tech) in Rosemead, California. Traditional letterpress printing was still king, but photolithography (a combination of the technologies of photography and lithography) was quickly becoming dominant.

What was the draw to this profession: “It was 1969 and I was 14 when I first started learning about the printing industry at Bosco Tech. After touring the Photolithography lab, with my parents, I knew I had found a home. Within two years, I was so captivated by the industry the program represented, as well as the teachers who taught me, that I simply HAD to become a teacher of photolithography. So, upon graduation, I started working for Bosco Tech as a lab assistant while I was going to California State University--Los Angeles to earn my teaching degree and credential. Years later, when I became the department chair, we rebranded the program ‘Graphic Communications Technology’ to coincide with the rest of the printing industry. After I left Los Angeles to come to Houston, the program was rebranded again as ‘Media Arts and Technology.’”

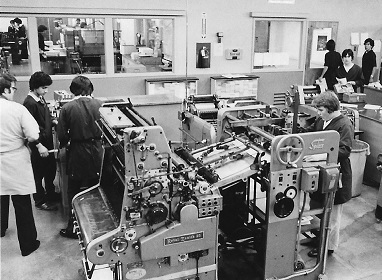

What were the cutting edge practices when you started in the industry: “The process, which seems so antiquated now, was state of the art at the time. We learned to typeset with electric keyboards called Friden Justowriters, which used punched paper tape to create justified lines of type. We used a layout process called ‘paste-up’ to position the typeset copy on illustration board, then photographed the boards using orthochromatic film. The resulting negative went through a process called ‘stripping.’ The material was placed on photo-sensitive printing plates and exposed to high intensity actinic light. The exposed area became the printing image, which eventually was mounted to a lithographic press and inked.”

What are the top advancements in the industry in the last 50 years: “In 1975, our school bought a Varityper phototypesetting machine, which could produce far more sizes and styles of type than the Friden Justowriter. Although the Varityper was pretty cool, it was expensive and broke down a lot. In the 1980s the maintenance contract was $10,000. I was very impressed when, in 1984, I attended a trade show and saw a little booth named Apple Computer with the brand new Macintosh computer. For the same $10,000 I was spending per year for the maintenance contract on our Varityper, I could buy three Macintoshes and a new-fangled laser writer. Without a doubt, the introduction of the Macintosh computer is the biggest change to the printing industry in my lifetime.”

The second major advancement in my lifetime is the method we use to create illustrations and capture images. “When I began in 1969, illustrations were drawn by hand and images were captured using film-based cameras. All of this process changed with the perfection of the charged-coupled-device (CCD) by Bell Labs in the 1980s. CCD-based scanners have completely replaced the use of orthochromatic film and process cameras. They are used to digitize illustrations and continuously tone photographs.”

The third most important technological revolution during my lifetime is page layout. “It used to be that type was set and pasted on an illustration board and then photographed. When the Apple Macintosh was released, it came at nearly the same time as laser printing and the release of Aldus PageMaker software (its descendent is now known as Adobe InDesign). PageMaker allowed a designer or technician to add text along with scanned images and vector illustrations to make complete pages. Whereas previous technologies required the use of separate methods of handling type and photographs, PageMaker could combine both of them into a single file.”

The fourth technological change is output. “The electrophotographic and ink jet processes are replacing photolithography, and every printed page can now be different and personalized. Through the use of print and database/data mining technologies, people can receive printed materials that are directly related to their likes. Of all the transcendent output methodologies, the most exciting today is inkjet. From producing custom fabrics used to make one-of-a-kind fashion, to banners that cover the sides of buildings, to stunning photographic reproductions, to billing statements that include personalized content--inkjet is the rising output technology.”

The fifth major technological transformation in my printing career is “transmedia”. “The slogan for the Digital Media program is ‘Getting the right message to the right person at the right time with the right media.’ What matters most to communicators is getting the message into the head of a person who is disposed to hear it. That means using all contemporary media--printed materials, websites, mobile apps, motion media, social media--in a media agnostic way. This is the core philosophy of the current Digital Media program. It is not designed to prepare a web designer or a printing press operator, or a filmmaker. It is designed to prepare graduates to be strategists or producers.”

What is your advice to students hoping to pursue careers in the industry: “I advise print and packaging students that they are going into an industry that is not dead, but reincarnated from the cheapest method of communication in the 1980s-1990s to one of exceptional opportunity. Personalization and targeted marketing have combined to increase effectiveness of printed marketing pieces. As a result, the beauty, features and cost of printed products have increased, as have profit margins. We also talk about the environmental impact of paper and that is it not terrible like they’ve been taught. Growing trees sequesters carbon dioxide from the air. Cutting trees down to make lumber and paper—and replacing them with new seedlings—actually decreases climate change because the carbon in the paper remains sequestered while the growing seedlings absorb it.”

What is next for the industry: “The biggest challenge will be its aging workforce. The combination of increased productivity and automation, along with the decrease in educational institutions that provide education in print, has resulted in fewer hires for the last few decades. Employees stayed in their positions, but automation made them more productive. Fewer young people were hired. The average age of a printing employee is early to mid-60s. These employees will retire soon and will have to be replaced.”

The biggest victory will be for printing companies to become Transmedia Marketing™ providers. Email, texting, social media, mobile apps, websites--these all are cheap ways to get a message out to both the masses and to targeted individuals. Combining data that can be gleaned from these electronic media, along with effective data analysis, can lead to the creation of a mailing list of people who can be sent stunningly beautiful and tactile printed objects that can often be the catalyst for a conversion (purchase). To me, victory will be in the hands of those who can strategically use all the media in a transmedia way.”