UH Invention Exclusively Optioned to NaNoEOR™ LLC

A nanotechnology developed at the University of Houston that shows promise for enhanced oil recovery (EOR) has entered a multi-phase manufacturing process intended to test and scale for mass nanofluid production.

The EOR nanotechnology invented by UH physicist Zhifeng Ren, director of the Texas Center for Superconductivity at UH, and postdoctoral fellow Dan Luo has been exclusively optioned to NaNoEOR™ LLC, an affiliate of Future Energy LLC.

“Dr. Ren and his team have introduced a novel and innovative idea of an exothermic reaction to reduce oil viscosity and we’re excited about the results that we have seen so far,” said Kent Hytken, CEO of Future Energy LLC.

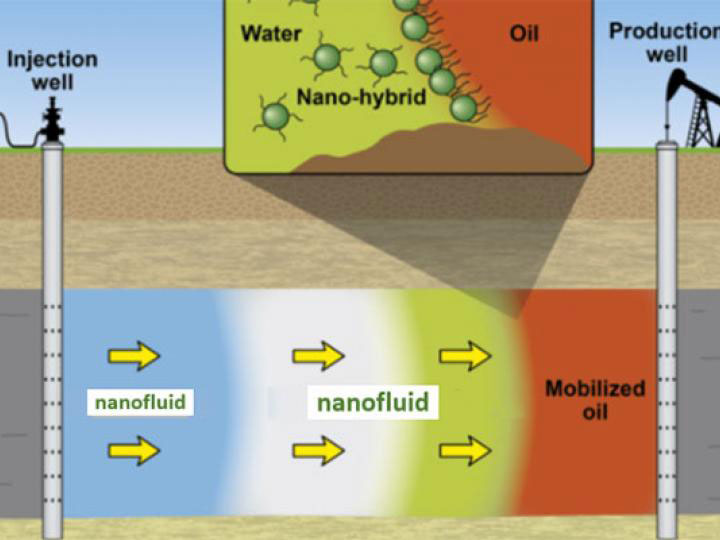

The NaNoEOR™ zero-emissions nanotechnology enables the nanofluid to be injected into a reservoir to significantly reduce the viscosity of heavy oil, oil sands and tight/shale oil deposits by causing an exothermic reaction. This exothermic reaction generates hydrogen gas that emulsifies the oil, decreases the interfacial tension between crude oil and water, and causes wettability alteration for improved sweep efficiency, maximizing oil mobility for increased oil production.

“This NaNoEOR™ technology can really be a game changer and transformative for oil recovery,” said Hytken. “The initial UH lab tests show evidence of a 94% reduction in viscosity of 13 API oil, something no researcher has been able to achieve thus far.”

Unlike inefficient and antiquated conventional steam technology currently used to reduce heavy oil viscosity, liquify and extract viscous oil deposits, NaNoEOR™ shows promise for increased oil production for a low cost per barrel of produced oil and may be more economical, as it does not require a large capital expense for equipment in EOR operations.

Most heavy oil wells today undergo thermal enhanced oil recovery through conventional steam technology, a proven method to reduce heavy oil viscosity and the main application used across today’s heavy oil industry. The manufacturing cost of steam requires a large investment in capital equipment and is not energy efficient, as large amounts of steam vaporizes at the surface and in the wellbore. This reduces the steam quality and limits steam injection to 2,000 feet, eliminating the possibility of extracting heavy oil at greater depths.

“From what we’ve seen so far, NaNoEOR™ is far superior to other EOR technologies developed,” said Hytken, who is the inventor of the eSteam™ downhole steam technology for heavy oil extraction operations.

Hytken is leading the effort to scale up the technology for mass production. “We are working on the initial nanofluid dispersion batch until it reaches the level needed for commercial production,” Hytken said. “If successful, Future Energy will continue to scale in larger batches to initially test the NaNoEOR™ nanotechnology in reservoirs in California, Texas, Canada, and Muscat, Oman.”

For more information about this nanotechnology, contact Kent Hytken at kent@futurenergyllc.com or visit futureenergyllc.com.

- Lindsay Lewis, UH Technology Bridge