The current flowing across two isolated

parallel plates is a very sensitive way of determining their

separation. If one of the plates is a flexible membrane the

separation is directly related to pressure across it. This

concept can be easily scaled down and integrated into micro and

nano mechanical systems (M/NEMS) that are enabling the merger of

technological revolutions such as the biomedical and the

nanotechnology fields (see caption below). This concept allows

devices capable of measuring extremely low flows (nano/pico

SCCM) as required for drug delivery, bioassays, DNA research,

and forensic medicine.

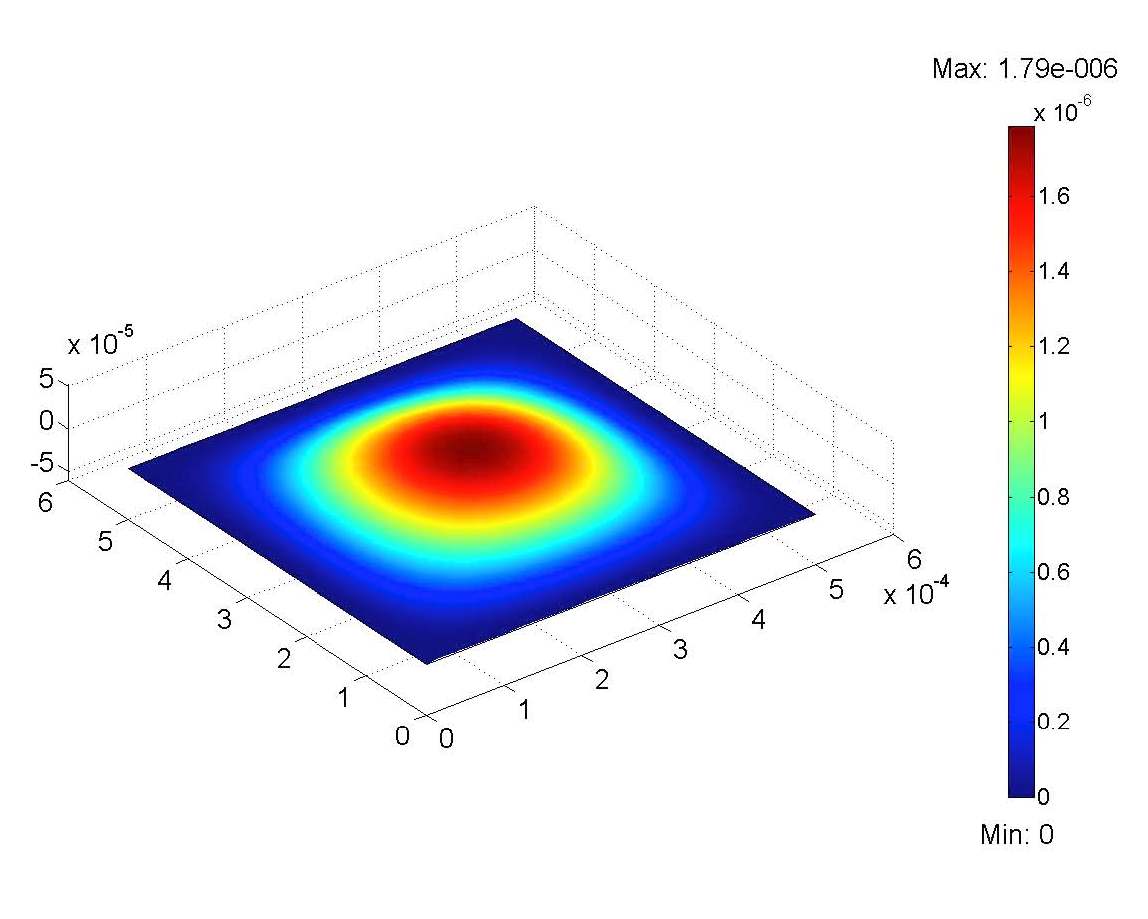

In our approach and in contrast to currently available piezoelectric, capacitive and piezoresistive pressure sensors, we are developing field emission based devices that have the advantage of a particularly wide dynamic pressure range using a single device. We optimized the field emission properties of BN layers deposited by ion beam assisted thermal evaporation, developed wet and dry processing methods and fabrication flow diagrams for a field emission pressure device. To avoid expensive process runs and achieve optimized designs for our sensors, extensive modeling and simulation studies were undertaken using commercially available COMSOL software. Of the materials investigated, TiN seems to have the most desirable membrane characteristics with respect to linearity and dynamic range. Funding for this project is continuing through a private company and the UH team is in the final stage of fabricating both electrical and mechanical parts of the sensor. These are specifically engineered nitride–based (BN, CN) cold cathodes and TiN sensing membranes.