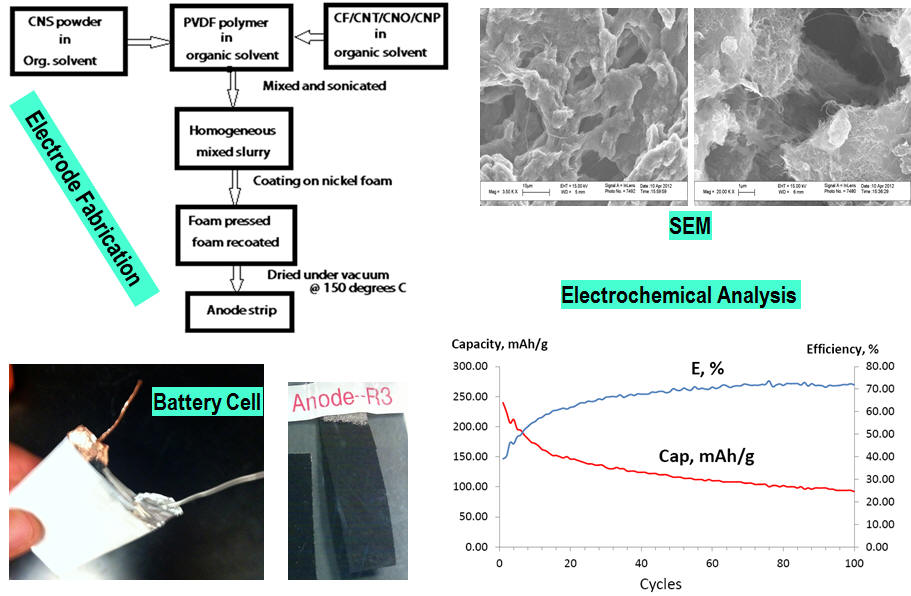

Nanostructured Carbon -based Electrodes for

Electrochemical Energy Storage Devices

The main objective of this project is to fabricate

innovative electrode components using carbon nanostructure

materials (CNS) such as

graphene-like, carbon nanotubes (CNT), and carbon

fibers.

The novelty in CNS is that they can be

manufactured from carbon byproducts, and have advantages that

result in a cost effective process with strong potential to

launch in an industrial set up.

Due to the nature of CNS blend, they

possess large surface areas that can be consolidated under

different conditions to reach desire levels of porosity (nano –

meso scale), from fully dense materials to highly porous

membranes. The

unique features and benefits of CNS as well as advantages over

the existing carbon-based technology include: 1) several times

larger surface area than activated carbon - generates extremely

high energy density. The open network

structure of CNS electrodes minimizes the diffusion path of

electrolyte ions, which is critical for charging the device. CNS

pores are easily accessible, whereas most of the surface area of

activated carbon is confined in a very small pores that limit

the diffusion of ions;

2) very high conductivity properties will increase the power

density burst of the device. CNS

electrodes are mechanically robust and show high conductivity (>

500 S/m) compared to AC (< 100 S/m);

3) availability of methods to create CNS based layers for better

power efficiency compared to metal oxides, conducting polymers,

xerogels, CNT, and AC.; and 4) compatibility with AC-based

technology and standard processes and equipment used for

fabrication of conventional Supercapacitor.