ANIMAL CARE OPERATIONS UPGRADES FACILITIES TO SAVE WATER, ENERGY

AND REDUCE WASTE

Here

at the university, there is important research conducted on a

daily basis, and critical to that effort is Animal Care

Operations. The Animal Care Operations staff takes care of

animals and the animal facilities that support the university�s

research effort in psychology, cardiac care, cancer and

optometry. The team works day in and day out to make sure the

animals are provided feed and water as well as an environment

that is clean and safe. The facilities are top notch and

compliant with all government regulations. Now, the team has

taken the next step to improve the facilities to make it more

sustainable by replacing older equipment and changing their

processes to save water, energy and drastically reduce waste. Here

at the university, there is important research conducted on a

daily basis, and critical to that effort is Animal Care

Operations. The Animal Care Operations staff takes care of

animals and the animal facilities that support the university�s

research effort in psychology, cardiac care, cancer and

optometry. The team works day in and day out to make sure the

animals are provided feed and water as well as an environment

that is clean and safe. The facilities are top notch and

compliant with all government regulations. Now, the team has

taken the next step to improve the facilities to make it more

sustainable by replacing older equipment and changing their

processes to save water, energy and drastically reduce waste.

David Brammer, Executive Director for Animal Care Operations,

said the first improvement was made to the facilities in October

2011 with the replacement of the

cage-washing system. The previous cage-washing system included a

tunnel washer and a rack washer that were originally installed

in 1978. These washers required continuous water to run

throughout the day, five days a week. Brammer said they estimate

that one of these machines used approximately 1,200 gallons of

water a day which had to be heated to 190 degrees. Both older

machines were replaced by one Green Power rack washer which uses

only 500 gallons per day for three and a half days out of the

week. The 500 gallons of water is also heated but only has to

reheat 26 gallons for each new wash. This new system is saving a

significant amount of energy and water for the university.

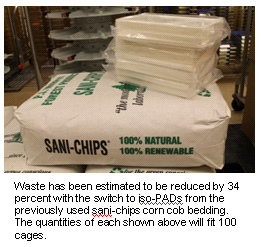

This month, all of the mice cages and racks will also be

replaced to reduce energy use and waste. Corn cob bedding, which

was used to line the bottom of the cages, will now be replaced

with iso-PAD bedding, a medical grade lightweight cotton pad.

�The corn cob bedding, which can have either fertilizer residue

or pesticide residue, is being replaced to eliminate this

influence on the research. The highly processed cotton fibers do

not have these residues and is much lighter. The added advantage

of being light weight means that less waste is disposed of in

the dumpsters,� Brammer said.

Brammer

estimates that once the new cages are in place, waste will be

reduced by 34 percent. Also, the new caging system requires less

space. A room that previously held 256 cages will now

accommodate 700 of the new cages. Brammer

estimates that once the new cages are in place, waste will be

reduced by 34 percent. Also, the new caging system requires less

space. A room that previously held 256 cages will now

accommodate 700 of the new cages.

�The caging system selected is the highest density caging system

available on the market. We can house more mice in less space.

This eliminates the need to build a new animal facility to

accommodate the increasing demands for mice in research,�

Brammer said.

The new caging system also uses the existing building exhaust

system to pull air through the cages. The previous caging system

required the use of separate blowers. The use of energy to run

the blowers will now be eliminated with the new system.

Even after all the enhancements to the caging areas, Animal Care

Operations decided to make an additional change to their

cleaning supplies and purchased mops that will require less

water and chemicals. The new mops use a micro fiber pad system

which is able to utilize only one gallon of diluted sanitizing

chemicals for up to 25 pads. The water in the mop buckets is not

contaminated by dirty mops as it is with conventional systems.

This allows the staff to use the solution in the buckets until

all of the water is utilized. This eliminates the need to dump

the water buckets and therefore saves approximately 100 gallons

of diluted chemicals from being dumped into the drains each day.

These enhancements at the Animal Care Operations are another way

that academic research and sustainable practices at UH are

improving the waste impact on the planet. For more information

on Animal Care Operations, visit the

Division of Research website.

For more information on the Office of Sustainability, visit

www.uh.edu/green.

|